Shenzhen Ledodm Lighting Co., Ltd

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Shenzhen Ledodm Lighting Co., Ltd

Shenzhen Ledodm Lighting Co., Ltd

LED Strip Blog

Views: 1097 Author: LEDODM Publish Time: 2023-01-28 Origin: LEDODM

As we all know that there is generally a problem of voltage drop for low-voltage led strip lights. Voltage drop, as the name implies, refers to the drop in voltage. For the led strip light, the voltage drop means that the brightness of the led strip light will decrease.

Usually, for 12V led strip lights, if the length more than 5 meters, there will be a voltage drop. For 24v led strip lights, if the length more than 10 meters, there will be a voltage drop. The result of the voltage drop is that the brightness at the end is low, resulting in the brightness will be darker than the start. if the voltage drop is large, it will also cause a large difference in the color (like below picture).

However, in the actual installation and application process, the led strip lights length used is often more than 5 meters or 10 meters. If have the voltage drops problem, it will lead to poor lighting effect and give people a very bad experience, so is there any way to solve the problem of voltage drop?

Here we can offer several solutions:

1.For the 12v led strip light, give it extra power if more than 5 meters. For 24V, give it additional power if more than 10 meters.

Below is the picture compare . The left one have voltage drop. While the right one is give extra power for the led strip .so the brightness and color is same .

2. Do the low voltage led strip light to constant current led strip light. The low-voltage constant-current light strip can be made for a super long length without voltage drop. For example can do 15m/roll 30m/roll no voltage drop.

What factors affect voltage drop?

Cable thickness: it is the single most significant factor affecting voltage drop: if you use a cable that is too narrow, this will certainly cause a decrease in voltage towards the end of your long cable run.

Cable composition: As with any circuit, the material a cable is made from will affect how well it conducts a current. The better the conductor, the further and more effectively it will carry a current from source.

LED Strip length: As a general rule, any continuous run of LED tape longer than 6 meter will start to suffer a voltage drop. But it’s no problem to design a LED tape installation longer than 6m that will avoid voltage drop.

How to Avoid Voltage Drop in LED Strip?

Strategies to Avoid Voltage Drop

1. Proper Sizing of Power Supply: Selecting an appropriately sized power supply is crucial for mitigating voltage drop. By calculating the total wattage of the LED strip and ensuring that the power supply can deliver the required voltage and current, you can minimize the impact of voltage drop.

2. Voltage Drop Calculations: Utilize voltage drop calculators to determine the appropriate wire gauge for the specific length and current requirements of the LED strip. By using thicker wires with lower resistance, you can effectively reduce voltage drop in the circuit.

3. Voltage Regulation: Implement voltage regulators or constant current drivers to maintain a consistent voltage across the LED strip, especially in installations where long runs of LEDs are involved. This ensures stable performance and prevents uneven illumination due to voltage fluctuations.

4. Distribution of Power Injection: In longer LED strip installations, strategically injecting power at multiple points along the strip can effectively combat voltage drop. By dividing the LED strip into sections and supplying power to each segment, you can maintain uniform brightness and minimize voltage drop.

5. Quality Components: Opt for high-quality LED strips, connectors, and power supplies to minimize voltage drop. Choosing components with lower resistance and superior conductivity can significantly reduce the impact of voltage drop on the performance and longevity of the LED lighting system.

6. Proper Installation Techniques: Ensure that the LED strip is installed according to manufacturer specifications, including secure connections and adequate heat dissipation. Proper installation minimizes resistance and optimizes the electrical conductivity of the LED lighting system, reducing the likelihood of voltage drop.

Voltage drop in LED strips is a common challenge that can impair the performance and longevity of the lighting system. By understanding the factors that contribute to voltage drop and implementing the strategies outlined in this comprehensive guide, users can effectively mitigate voltage drop and ensure optimal brightness, color consistency, and longevity of their LED strip installations. With proper planning, quality components, and strategic implementation, voltage drop can be successfully avoided, maximizing the benefits of LED lighting for various applications.

Is voltage drop harmful to LED strips?

LED strip voltage drops are generally not harmful to LED strips, as it is a form of supplying them with lower voltage than initially expected. However, the voltage drop usually represents the conversion of electrical energy to thermal energy in the resistor, which generates a lot of heat. Another problem is that the effect of brightness is affected, so it is a problem if the voltage drop is too large.

How Do I Fix LED Strip Light Voltage Drop on My Power Supply?

Fixing LED strip light voltage drop on a power supply involves several steps, including identifying the cause of the voltage drop, troubleshooting the power supply, and implementing solutions to rectify the issue. Below is a detailed guide on how to fix LED strip light voltage drop on a power supply.

LED strip lights have gained popularity due to their energy efficiency, flexibility, and vibrant lighting effects. However, voltage drop issues can occur, leading to uneven brightness or malfunctioning of the LED strips. Addressing voltage drop on the power supply is crucial to ensure the optimal performance of LED strip lights.

Understanding LED Strip Light Voltage Drop

Voltage drop refers to the decrease in voltage along the length of the LED strip light. This can occur due to various factors such as inadequate power supply, excessive length of the LED strip, or poor wiring connections. Understanding the causes of voltage drop is essential to effectively troubleshoot and fix the issue.

Identifying the Cause of Voltage Drop

Before implementing solutions, it's important to identify the specific cause of the voltage drop. This can be done through a systematic process of inspection and testing.

Check Power Supply Specifications

Verify that the power supply's output voltage and current ratings match the requirements of the LED strip lights. Ensure that the power supply has sufficient capacity to power the entire length of the LED strips without excessive voltage drop.

Measure Voltage Along the LED Strip

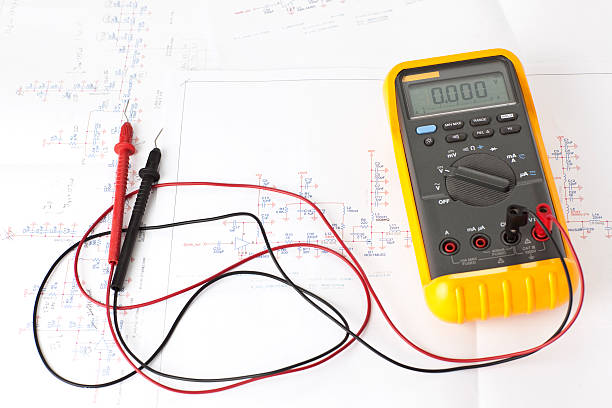

Use a multimeter to measure the voltage at various points along the LED strip. Note any significant voltage drop from the power supply's output voltage to the far end of the strip.

Inspect Wiring and Connections

Examine the wiring connections, especially at the interconnection points and the terminals of the power supply. Loose or inadequate connections can contribute to voltage drop.

Assess Length of LED Strip

Evaluate whether the length of the LED strip exceeds the recommended maximum length for the specific type of LED strip and power supply being used. Longer LED strips can experience higher voltage drop.

Troubleshooting the Power Supply

Once the cause of the voltage drop is determined, troubleshooting the power supply and associated components is essential to identify any faults or deficiencies.

Test the Power Supply Output

Use a multimeter to measure the output voltage of the power supply under load conditions. Ensure that the voltage remains within the specified range and does not fluctuate excessively.

Check for Overheating

Inspect the power supply for overheating, which can indicate overload conditions or internal faults. Overheating can contribute to voltage drop and reduce the longevity of the power supply.

Verify Power Supply Quality

Assess the quality and reliability of the power supply. Low-quality or counterfeit power supplies may not provide stable output voltage, leading to voltage drop issues.

Implementing Solutions

Based on the findings from the previous steps, implement the appropriate solutions to address the LED strip light voltage drop on the power supply.

Upgrading the Power Supply

If the existing power supply is inadequate or faulty, consider upgrading to a higher capacity and reliable power supply with better voltage regulation. Select a power supply that matches the voltage and current requirements of the LED strip lights.

Distributing Power with Amplifiers

For longer LED strip installations, use signal amplifiers or repeaters to boost the voltage and maintain uniform brightness along the entire length of the LED strips. Amplifiers can effectively mitigate voltage drop in extended LED strip setups.

Improving Wiring and Connections

Ensure secure and proper wiring connections throughout the LED strip installation. Use high-quality connectors and soldering techniques to minimize resistance and voltage drop at connection points.

Segmenting the LED Strips

Divide long LED strips into shorter segments and power them separately from the power supply. This reduces the voltage drop by distributing the load across multiple power sources.

Voltage Drop Compensation

Employ specialized voltage drop compensation components or techniques, such as voltage boosters or voltage drop correction modules, to actively counteract voltage drop effects and maintain consistent brightness across the LED strips.

Resolving LED strip light voltage drop on a power supply requires a methodical approach, from identifying the root cause of the voltage drop to implementing effective solutions. By understanding the factors contributing to voltage drop and taking proactive measures, it is possible to optimize the performance and longevity of LED strip light installations.

Low-voltage LED Strip Light Voltage Boosting and Compensation Techniques

Boosting and compensating voltage for low-voltage LED strip lights is an important consideration when designing lighting installations.

1. Voltage Boosting Techniques

a. Voltage Regulators: One commonly used technique to boost voltage is by employing voltage regulators. These devices can increase the input voltage to match the required voltage for the LED strip lights. They come in various types, such as linear regulators and switching regulators, each with its advantages and disadvantages.

- Linear regulators are simple and inexpensive, but they are inefficient and dissipate excess heat.

- Switching regulators are more efficient and dissipate less heat but can be more complex and costly.

b. Step-Up Converters: Another technique is to use step-up converters or boost converters. These devices increase the input voltage to a higher level suitable for the LED strip lights. Step-up converters are typically more efficient than linear regulators as they utilize power conversion techniques like inductive energy storage to elevate the voltage.

c. DC-DC Converters: DC-DC converters are versatile devices that can convert one DC voltage level to another, making them suitable for boosting low-voltage inputs. These converters can be designed to provide the desired output voltage required for the LED strip lights.

2. Voltage Compensation Techniques

a. Parallel Wiring: One way to compensate for voltage drop is by employing parallel wiring. By dividing the LED strip light installation into multiple sections and connecting them in parallel, the overall resistance and voltage drop are reduced. This technique ensures more uniform brightness across the entire strip and minimizes the impact of voltage drop.

b. Thick Wire Gauge: Using thicker wire gauge for the power supply connections helps reduce the resistance and subsequent voltage drop. Thicker wires can handle higher current loads with less voltage loss. Calculating the appropriate wire gauge based on the current and length of the LED strip light installation is essential for effective voltage compensation.

c. Voltage Amplifiers: Voltage amplifiers can be used to compensate for voltage drop by amplifying the voltage level at various points along the LED strip lights. These devices receive a lower voltage input and amplify it to the desired level, ensuring consistent brightness.

Boosting and compensating voltage for low-voltage LED strip lights is crucial to ensure optimal brightness and functionality. Techniques like voltage regulators, step-up converters, and DC-DC converters can increase the voltage to match the requirements of the LEDs. Additionally, voltage compensation techniques, such as parallel wiring, thick wire gauge, and voltage amplifiers, help minimize the effects of voltage drop. Understanding and implementing these techniques will result in a more reliable and efficient LED strip light installation.

Voltage Drop Effects on Different LED Colors

Voltage drop can have different effects on different colors of LEDs. The voltage required for various colors of LEDs isn’t the same. For instance, a blue or white LED voltage drop might be different than a red LED. When voltage supply drops, these colored LEDs may not fade equally, leading to a color shift in RGB or RGBW LED strip lights across the strip length.

Voltage drop refers to the decrease in voltage that occurs when current flows through a component or a portion of a circuit. This phenomenon is particularly relevant when it comes to light-emitting diodes (LEDs), as the voltage drop across an LED directly affects its performance and characteristics, including its color.

1. Impact of Voltage Drop on LED Colors

A. Red LEDs: Red LEDs have a lower voltage drop compared to other colors. As a result, they tend to be more tolerant of variations in the input voltage. This means that red LEDs can still emit light and operate relatively well, even when subjected to slight voltage drops. However, if the voltage drop becomes too significant, the red LED may become dimmer and less efficient, resulting in a noticeable decrease in brightness and color intensity.

B. Green LEDs: Green LEDs have similar characteristics to red LEDs in terms of voltage tolerance. They can still function and emit light at slightly lower voltages, but excessive voltage drops can cause them to dim or fail to light up altogether. Green LEDs typically have a forward voltage drop ranging from 2.0 to 3.5 volts.

C. Blue and White LEDs: Blue and white LEDs have higher forward voltage drops compared to red and green LEDs. Consequently, these colors are more sensitive to voltage drops. Even slight decreases in voltage can significantly impact the performance and appearance of blue and white LEDs. At lower voltages, blue and white LEDs may appear dimmer or emit a different hue. It is crucial to provide a stable and appropriate voltage supply to blue and white LEDs to ensure optimal performance.

3. Brightness and Efficiency

Voltage drop affects both the brightness and efficiency of LEDs. As the voltage decreases, the amount of current flowing through the LED reduces, resulting in a decrease in brightness. LEDs operate most efficiently when they receive the necessary voltage to reach their maximum current rating. If the voltage drop is excessive, the LED may not reach its maximum brightness potential, leading to reduced efficiency.

4. Color Temperature

The color temperature of an LED refers to its perceived color appearance, ranging from warm white to cool white. Voltage drop can affect the color temperature of LEDs, especially in blue and white LEDs. When these LEDs experience lower voltages, they may emit a warmer or more yellowish light instead of the desired cool white or blue light. Care must be taken to provide the appropriate voltage to ensure accurate color representation.

5. Driving LEDs with Constant Current Source

To mitigate the effects of voltage drop, it is often recommended to drive LEDs using a constant current source rather than a simple voltage source. A constant current driver maintains a consistent current flow through the LED, compensating for any variations in voltage drop. This ensures that the LED operates at its desired performance level, irrespective of voltage fluctuations.

LED Strip Light Voltage drop for LED can lead to uneven lighting and dimming issues

Voltage drop for LED can lead to uneven lighting and dimming issues. The higher the voltage drop, the more noticeable the light deterioration at the end of LED strip. LEDs near the power supply will have higher brightness while those at the far end may appear dimmer. It affects the uniformity of light output, making it a crucial consideration for professional lighting installations.

Also, when calculating the power needs for dimming, you must account for LED voltage drop. Without accounting for this, the end of your strip may be too weak to dim correctly when voltage drop led strip is high.

Consequences of Voltage Drop

Voltage drop in LED strip lights can result in several undesirable consequences, including uneven lighting, color inconsistency, and dimming issues. As the voltage decreases along the length of the strip, the LEDs located further from the power source will receive less voltage, leading to a reduction in brightness and color intensity. This can create a noticeable variation in lighting quality, especially in longer runs of LED strip lights. Additionally, voltage drop can result in erratic dimming performance, causing flickering or unstable brightness levels, which detract from the overall aesthetic and functionality of the lighting installation.

Strategies to Mitigate Voltage Drop

To address the impact of voltage drop on LED strip lights, it is essential to implement strategies that minimize the resistance in the electrical circuit and maintain consistent voltage levels across the entire length of the strip. This can be achieved through various approaches, including the following:

1. Proper Sizing of Conductors: Using the appropriate gauge of wire for the specific length and power requirements of the LED strip installation is crucial in minimizing voltage drop. Thicker conductors have lower resistance and can effectively reduce the voltage drop along the length of the circuit.

2. Voltage Regulation: Implementing voltage regulation devices such as LED strip light amplifiers or voltage boosters can help maintain consistent voltage levels, especially in longer runs of LED strip lights. These devices can compensate for the voltage drop and ensure uniform brightness and color consistency throughout the installation.

3. Quality Connections: Ensuring secure and high-quality connections between the power supply, LED strip, and any additional components is essential for minimizing voltage drop. Properly crimped or soldered connections reduce resistance and prevent voltage loss at connection points.

4. Segmented Power Feeds: Dividing longer runs of LED strip lights into shorter segments with individual power feeds can mitigate voltage drop by reducing the overall length that the current must travel. This approach helps maintain consistent voltage levels and lighting performance across the entire installation.

5. Voltage Drop Calculations: Conducting thorough voltage drop calculations based on the specific parameters of the LED strip light installation, including the length of the run, current requirements, and conductor properties, can aid in determining the appropriate measures to counteract voltage drop and ensure optimal lighting performance.

Do all LED strip lights have a voltage drop?

Due to the design principle of constant voltage led strip lights, 5V led strips, 12V led strips, and 24V led strips will inevitably have voltage drops during long-distance operation.

High voltage led strip lights use AC high voltage electricity with strong energy. Compared with low voltage led strip lights in the same running length like 10m, at the fifth meter, the current flowing through is smaller and the voltage is more sufficient, so high voltage led strips can run for a distance of 50 meters without voltage drop.

When it comes to constant voltage, it is hard not to think of constant current. Due to the rated current of the constant current led strip light, a more constant current IC in the strip, the voltage will not fluctuate greatly during the led strip operation, thus ensuring brightness consistency. Constant current led strip lights are also one of the options for long-distance running.

Causes of Voltage Drop in LED Strip Lights

1. Resistance of the Conductive Material

The primary cause of voltage drop in LED strip lights is the inherent resistance of the conductive material used in the circuitry. Copper traces or other conductive materials on the flexible circuit board of the LED strip offer resistance to the flow of electrical current, resulting in a drop in voltage.

2. Length of the LED Strip

As the length of the LED strip increases, the total resistance of the conductive material also increases, leading to a greater voltage drop. Longer LED strips experience more significant voltage drops compared to shorter ones, especially when powered from a single power source.

3. Current Load

The amount of current drawn by the LEDs on the strip contributes to the overall voltage drop. Higher current loads result in greater voltage drops, particularly when the power source and the LED strip are not adequately matched.

4. Inadequate Wiring and Connections

Poor quality or undersized wiring, as well as loose or inadequate connections, can exacerbate voltage drop issues in LED strip light installations. Resistance introduced by faulty wiring and connections can further contribute to voltage drop.

Effects of Voltage Drop on LED Strip Lights

Voltage drop can lead to several undesirable effects in LED strip light installations, including:

1. Reduced brightness and uneven illumination along the length of the strip.

2. Dimming of LEDs located farther from the power source.

3. Overheating of the strip due to increased current flow in an attempt to compensate for the voltage drop.

4. Potential damage to the LEDs and associated components due to excessive current flow.

Solutions to Minimize Voltage Drop

1. Voltage Drop Calculations

Before installing LED strip lights, it is crucial to calculate the expected voltage drop based on the length of the strip, current load, and the specifications of the conductive material. Several online voltage drop calculators are available to assist in these calculations.

2. Proper Power Supply Sizing

Selecting an appropriate power supply that matches the voltage and current requirements of the LED strip is essential to minimize voltage drop. Choosing a power supply with a higher voltage than the LED strip's nominal voltage can compensate for voltage drop over longer distances.

3. Voltage Injection or Boosting

For longer LED strip installations, voltage injection or boosting techniques can be employed to counteract voltage drop. This involves introducing additional power supplies or voltage boosters at strategic points along the length of the strip to maintain adequate voltage levels.

4. High-Quality Wiring and Connections

Using high-quality, appropriately sized wiring and making secure, reliable connections can help minimize additional resistance and reduce the overall impact of voltage drop in LED strip light installations.

5. Voltage Drop-Resistant LED Strips

Some manufacturers offer LED strips with special designs or materials that minimize the effects of voltage drop. These strips are engineered to maintain more consistent brightness across longer lengths.

6. Consultation with Lighting Experts

For complex LED strip light installations or applications with specific requirements, seeking guidance from lighting professionals or electrical engineers can help in designing effective solutions to mitigate voltage drop issues.

How to Accurately Measure LED Strip Light Voltage Drop?

Tools for Accurate Measurement

1. Multimeter: A digital multimeter capable of measuring voltage is essential for accurately assessing voltage drop along the length of an LED strip light installation.

2. Voltage Drop Calculator: Various online tools and software applications are available to calculate voltage drop based on conductor specifications, current levels, and length.

3. Wire Gauge Chart: Reference charts displaying the ampacity and voltage drop characteristics of different wire gauges aid in selecting the appropriate conductor size for LED strip light installations.

Methods for Measuring LED Strip Light Voltage Drop

1. Setting Up the Multimeter: Begin by selecting the voltage measurement function on the multimeter. Ensure that it is set to the appropriate voltage range based on the expected voltage drop.

2. Identifying Measurement Points: Determine the locations along the LED strip light installation where voltage drop measurement will occur. These points should cover the beginning, middle, and end of the installation to capture variations.

3. Connecting the Multimeter: Place the multimeter probes at the chosen measurement points. The red probe should contact the positive terminal, while the black probe connects to the negative terminal of the LED strip lights.

4. Recording Measurements: Take voltage readings at each measurement point and record the values. Repeat the process for additional segments of the installation to gather comprehensive data.

Tips for Addressing Voltage Drop in LED Strip Light Installations

1. Proper Wire Gauge Selection: Choose a wire gauge that minimizes voltage drop based on the length and current requirements of the LED strip light installation.

2. Voltage Regulation Devices: Implement voltage regulation components such as buck-boost converters or voltage amplifiers to maintain consistent voltage levels along the LED strip lights.

3. Mid-Run Power Injection: Incorporate additional power sources or injection points along lengthy LED strip light installations to mitigate voltage drop at distant segments.

4. Efficient Wiring Layout: Optimize the wiring layout to minimize unnecessary bends, splices, or extended runs, which can contribute to increased voltage drop.

5. Regular Maintenance and Inspection: Periodically assess the voltage drop across the LED strip light installation to identify any changes or deteriorations that may impact performance.

Accurately measuring LED strip light voltage drop is essential for optimizing the performance and longevity of LED installations. By understanding the principles of voltage drop, utilizing appropriate measurement tools and techniques, and implementing effective mitigation strategies, individuals and professionals can ensure that LED strip lights operate at their optimal brightness and efficiency. Continual monitoring and proper maintenance contribute to a reliable and consistent LED lighting experience, ultimately enhancing the quality of illumination in various applications.

How about the Super Long Constant Current LED Strip?

The Super Long Constant Current LED Strip is an innovative lighting product that has gained significant popularity in recent years due to its energy efficiency, durability, and versatility. This type of LED strip is designed to provide a stable and consistent current output, ensuring reliable and uniform illumination across longer lengths, making it suitable for a wide range of residential, commercial, and industrial applications.

Constant voltage led strip wiring diagram

Super long constant current led strip wiring diagram

The Super Long Constant Current LED Strip is a type of light-emitting diode (LED) product that is characterized by its ability to maintain a constant current output over extended lengths. Unlike standard LED strips, which may experience voltage drop and inconsistent illumination over longer distances, constant current LED strips are engineered to deliver a stable and uniform brightness across the entire length of the strip. This is achieved through the integration of specialized drivers and circuitry that regulate the current flow to each LED, ensuring optimal performance and longevity.

Features and Specifications

Super Long Constant Current LED Strips are available in a variety of specifications to accommodate different lighting requirements. Key features and specifications may include:

1. Length: These LED strips are available in extended lengths, ranging from tens to hundreds of feet, allowing for seamless and continuous illumination in large-scale installations.

2. Constant Current Design: The constant current design ensures that each LED receives a consistent level of electrical current, resulting in uniform brightness and color temperature along the entire length of the strip.

3. High Efficiency: Utilizing advanced LED technology, these strips offer high energy efficiency, consuming significantly less power than traditional lighting sources while delivering equivalent or superior illumination.

4. Color Options: Super Long Constant Current LED Strips are available in a range of color options, including warm white, cool white, RGB, and single-color variants, providing flexibility for various lighting designs and applications.

5. Flexible or Rigid Forms: These LED strips are available in both flexible and rigid formats, allowing for versatile installation on different surfaces and in various configurations.

6. IP Ratings: Many constant current LED strips are designed with IP (Ingress Protection) ratings, making them suitable for indoor and outdoor use, as they are resistant to dust, moisture, and environmental fluctuations.

Benefits and Advantages

The use of Super Long Constant Current LED Strips offers several benefits and advantages compared to conventional lighting solutions. Some of the key benefits include:

1. Uniform Illumination: The constant current design ensures consistent brightness and color rendering across the entire length of the LED strip, eliminating the uneven lighting typically associated with voltage drop in standard LED strips.

2. Energy Efficiency: With high-efficiency LEDs and optimized current regulation, these strips consume less energy, resulting in reduced electricity costs and environmental impact.

3. Longevity and Reliability: The precise current control and robust construction contribute to an extended lifespan, reducing the frequency of maintenance and replacement compared to traditional lighting sources.

4. Versatility: Super Long Constant Current LED Strips can be used for a wide range of applications, including cove lighting, architectural accents, task lighting, signage, and decorative installations, due to their flexibility, color options, and weather-resistant properties.

5. Customization: Depending on the specific requirements of a project, these LED strips can often be customized in terms of length, color temperature, and brightness, providing tailored lighting solutions for various applications.

Applications

The Super Long Constant Current LED Strip is suitable for diverse lighting applications in residential, commercial, and industrial settings. Some common applications include:

1. Architectural Lighting: Illuminating building facades, interior spaces, and structural elements with continuous, uniform light, enhancing visual appeal and creating distinctive design effects.

2. Retail and Hospitality: Highlighting merchandise, creating ambient atmospheres, and accentuating architectural features in retail stores, hotels, restaurants, and entertainment venues.

3. Outdoor Landscape Lighting: Enhancing outdoor landscapes, pathways, and architectural features with durable and weather-resistant LED strips, contributing to safety and aesthetics in exterior environments.

4. Display and Signage: Backlighting signage, displays, and visual merchandising elements with vibrant and consistent illumination to attract attention and enhance visibility.

5. Cove and Accent Lighting: Installing concealed lighting in coves, shelves, and recessed areas to provide soft, indirect illumination and visual interest in residential and commercial spaces.

6. Industrial and Warehouse Lighting: Providing high-output, energy-efficient illumination in large industrial facilities, warehouses, and manufacturing environments for improved visibility and productivity.

Installation Considerations

When installing Super Long Constant Current LED Strips, several factors should be taken into consideration to ensure optimal performance and longevity:

1. Proper Power Supply: Selecting an appropriate constant current LED driver or power supply with sufficient wattage and voltage output to accommodate the total length of the LED strip(s).

2. Thermal Management: Ensuring adequate heat dissipation and ambient temperature control to prevent overheating and maintain the longevity of the LED strip components.

3. Mounting Surfaces: Choosing suitable mounting surfaces and methods, such as aluminum profiles, heat sinks, or adhesives, to secure the LED strips and facilitate heat transfer for optimal performance.

4. Environmental Conditions: Considering environmental factors such as moisture, dust, UV exposure, and temperature fluctuations when selecting IP-rated LED strips for outdoor or harsh indoor environments.

Market Trends and Future Prospects

The market for Super Long Constant Current LED Strips continues to experience growth and innovation, driven by ongoing advancements in LED technology, lighting design trends, and sustainable development objectives. Some notable market trends and future prospects include:

1. Smart Lighting Integration: Integration with smart lighting systems and control interfaces, enabling customizable dimming, color adjustments, and scheduling for enhanced energy management and user experience.

2. Human-Centric Lighting: Integration of tunable white options and circadian lighting principles, offering dynamic control over color temperatures to support human well-being and productivity in various environments.

3. Customized and Dynamic Effects: Growing demand for customized lighting designs and dynamic effects in architectural, retail, and entertainment settings, facilitated by advanced control systems and programmable LED technologies.

4. Sustainable Initiatives: Continued emphasis on energy efficiency, recyclability, and sustainable manufacturing practices, driving the development of eco-friendly LED strip products and promoting circular economy principles.

5. Integration with IoT and Connectivity: Leveraging the Internet of Things (IoT) and wireless connectivity for remote monitoring, data analytics, and interactive lighting experiences in smart buildings and urban environments.

In conclusion, the Super Long Constant Current LED Strip represents a compelling lighting solution that offers consistent, energy-efficient, and versatile illumination capabilities for a wide range of applications. With ongoing technological advancements and evolving market trends, constant current LED strips are poised to play a significant role in shaping the future of lighting design and sustainability initiatives across various industries. As demand for efficient and customizable lighting solutions continues to grow, the Super Long Constant Current LED Strip is positioned to contribute to a more vibrant, sustainable, and connected built environment.

If you have a better solution to the voltage drop of the low-voltage led strip light, Also please let us know. Let us learn and progress together. I also hope to bring more professional knowledge to the partners who in the LED strip industry.

Subscribe to our newsletters. Free Sample Available!